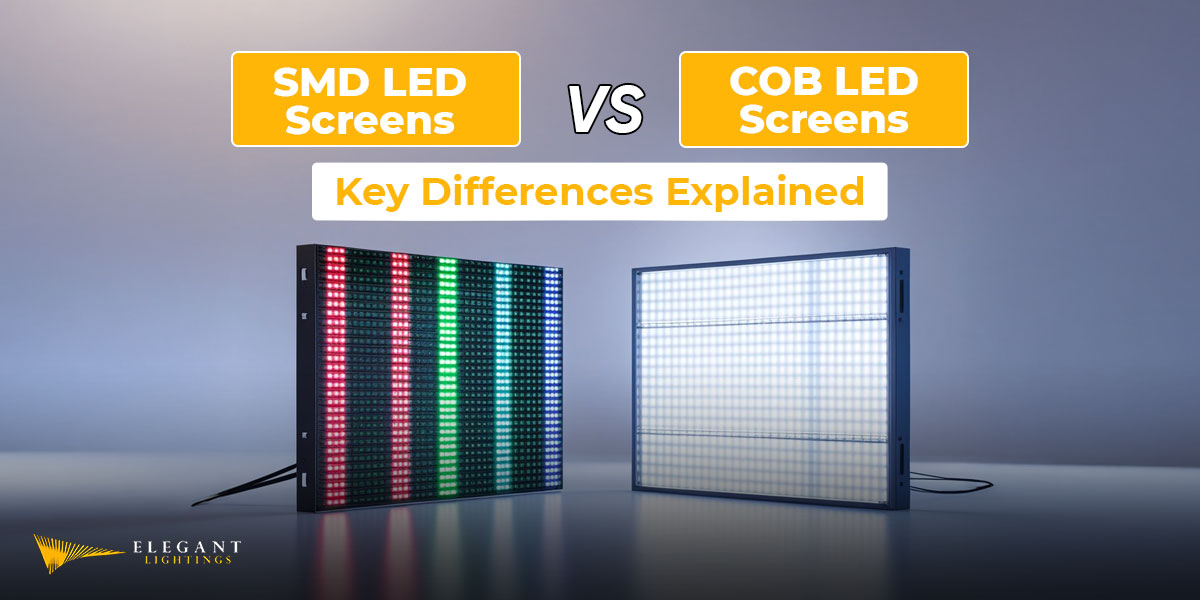

LED displays are everywhere: from concert stages to corporate lobbies.

What's on this page:

But have you ever wondered why some screens look perfectly smooth up close, while others show a distinct grid of dots?

The answer lies in the core technology behind them: SMD (surface-mounted) or COB (chip on board).

And if you’ve heard of these LED screen types but don’t know how they are different from one another, I am glad you are here!

In this blog, I will break down the key differences between SMD vs COB LED screens. I will also help you decide which one you should pick for your lighting requirements.

Let’s dive in!

SMD vs COB LED Screen: Table of Contents

- SMD vs COB LED Screen: Table of Differences

- What is an SMB LED Screen?

- What is a COB LED Screen?

- Key Differences Between SMD vs COB LED Screens

- Which LED Screen Should You Choose?

- Elegant Lightings: Your Reliable LED Screen Provider

- SMD vs COB LED Screen: FAQs

SMD vs COB LED Screen: Table of Differences

Need a quick answer? I’ve got you covered! Here’s a quick rundown of the key differences between SMD and COB LED screens:

| Feature | SMD LED Screen | COB LED Screen |

| Surface | Grainy, with visible gaps and grid lines. | Smooth, seamless, and flat. |

| Durability | Fragile; LEDs can be dislodged. | Rugged and impact-resistant. |

| Image Quality | Good color and contrast, but the grid can be visible. | Superior color uniformity and contrast; no grid. |

| Best For | Cost-effective signage, rental screens, and large billboards. | High-end control rooms, luxury retail, immersive spaces. |

| Cost Perspective | Lower initial cost, higher potential maintenance. | Higher initial investment, lower lifetime cost. |

What is an SMD LED Screen?

An SMD (Surface-Mounted Device) LED screen is a type of screen that is built by placing or mounting individual pre-packaged LEDs onto the surface of a circuit board.

It’s like a tiling floor where each LED is a separate tile that has been placed onto the floor with a small gap around it.

The individual LEDs are thus self-contained units with red, green, and blue chips housed inside a tiny plastic casing.

This method of creating an LED screen means that when the screen is off or displaying dark content, you can often see the tiny, distinct dots of the LEDs and the grid-like lines between them.

SMD technology is the predominant process used to manufacture LED screens and offers good image quality. However, its modular nature makes it much less robust compared to COB LEDs. This also exposes SMD LEDs to damage from impact or moisture.

What is a COB LED Screen?

A COB (Chip-on-Board) LED screen represents the next evolution in display technology.

Here’s how it works: instead of using pre-packaged LEDs, it involves mounting tiny, bare LED chips directly onto the circuit board.

These unprotected chips are then encapsulated under a smooth, continuous layer of epoxy resin. This process creates a single, unified, and flat surface.

Imagine it like a perfectly polished wooden table instead of a floor with individual tiles. That’s what you get with the seamless quality of a COB screen!

Its design eliminates the visible grid lines found in SMD screens, resulting in a smoother image, superior durability, and better protection against the elements.

This is why COB LED is a more advanced and future-proof lighting solution for commercial spaces and events.

COBs also work perfectly for both outdoor and indoor LED display environments.

Key Differences Between SMD vs COB LED Screens

There are five fundamental differences between COB and SMD screens:

1. Surface & Pixel Gaps

- COB LED: Features a perfectly smooth and seamless surface with no visible gaps between pixels. This is because the LEDs are coated with a protective layer of epoxy resin.

- SMD LED: Has a grainy surface with visible black gaps between the individual, packaged LEDs. You can see this in the form of grid lines (especially if you are looking at the screen from a close angle).

Check out this guide on Indoor vs Outdoor LED screens to find out which one matches your requirements.

2. Durability & Physical Protection

- COB LED: Highly rugged and impact-resistant due to its protective epoxy coating. The resin seal also makes it easy to clean with water and protects against moisture, dust, and corrosion.

- SMD LED: More fragile because individual LEDs can be knocked off during handling or cleaning. They are more easily damaged and require careful maintenance.

3. Reliability & Failure Rate

- COB LED: Offers extremely high reliability with a very low pixel failure rate and protection against solder joint issues. This also means they have a higher lifecycle.

- SMD LED: Has a higher risk of dead pixels because the screen as a whole is a complex assembly of individual components, any of which can fail over time.

4. Image Quality & Viewing Experience

- COB LED: Offers far superior color uniformity, higher contrast, and a smoother image without visual disruption from grid lines. So, if you want to create a more immersive viewing experience, COB LED screens are the ones you should choose.

- SMD LED: Delivers decent contrast and color, but the image quality can be compromised by the visible spaces between pixels. The gridlines are especially noticeable in fine-pitch applications.

5. Cost & Long-Term Value

- COB LED: Higher initial investment, but offers a lower total cost of ownership due to minimal maintenance, rare repairs, and exceptional long-term reliability.

- SMD LED: Lower initial cost, but can incur higher lifetime maintenance and repair expenses, providing lower long-term value.

Which LED Screen Should You Choose?

Not sure which LED screen will suit your needs? I’ve got you covered!

Check out the following scenarios and see which one best describes your requirements:

Choose SMD LED Screens When:

- You need a cost-effective solution for digital signage in environments where the highest image quality isn’t critical, such as basic informational displays.

- You are in the rental and staging business and need lightweight, modular panels for temporary events like trade shows or conferences.

- For large-format, long-distance outdoor billboards, where your viewers will be far away and pixel density is not a huge concern.

- Your project has a tight upfront budget, and the display won’t be subject to high traffic or potential physical impact.

- For standard indoor LED screens used for advertising in malls or retail spaces, where the screen is viewed from a distance and operational hours are limited.

Choose COB LED Screens When:

- You require a high-end display for a control room or broadcast studio where 24/7 reliability, color accuracy, and seamless visuals are non-negotiable.

- For luxury retail, corporate lobbies, and galleries, where impeccable image quality and a premium, seamless appearance are needed to enhance brand perception.

- In high-traffic public spaces like museums, airports, or hotel lobbies, the screen must withstand potential impact and be easy to clean and maintain.

- For creating immersive environments in home theaters, simulators, or event stages, where superior contrast, HDR performance, and a smooth image without grid lines are essential.

- When you need a curved video wall for applications like command centers or experiential marketing, as COB’s seamless nature provides a more uniform and visually continuous curve.

Elegant Lightings: Your Reliable LED Screen Provider

Through this blog, we have explored COB and LED screens along with the differences between them.

So, which one should you choose? The answer depends on the specific project requirements you have regarding image quality, durability, and budget. There’s no one-size-fits-all answer, but there is a perfect fit for your vision!

Still unsure which LED screen is right for you?

We’re here to help!

At Elegant Lightings, we don’t just sell screens: we provide solutions.

Our experts are here to guide you through the entire process, from understanding the core difference between SMD and COB LED to designing a system that delivers on your goals.

Whether you need a reliable SMD LED for a short-term rental or a state-of-the-art COB LED video wall for a permanent installation, we are your reliable partner for both sales and rentals.

Ready to illuminate your space? Connect with us today for a free consultation!

SMD vs COB LED Screen: FAQs

1. What is the main difference between SMD and COB LED?

COB LEDs have a seamless, resin-coated surface for a smoother image, while SMD LEDs have visible gaps between individual pixels, creating a grid effect.

2. Which is better for an indoor LED screen: SMD or COB?

For basic indoor signage, SMD is cost-effective. For high-traffic areas or where superior image quality is critical, COB is the better, more durable choice.

3. Are COB screens considered fine pitch LED displays?

Yes, COB technology is excellent for fine pitch LED displays as it eliminates the grid lines, creating a seamless viewing experience even up close.

4. How does COB improve LED video wall technology?

The COB (Chip On-board) approach creates a perfectly smooth surface without gaps, making it ideal for curved video walls and delivering a more immersive, uniform visual experience.

5. Is COB vs SMD LED more energy-efficient?

COB LEDs are generally more energy-efficient compared to SMD LEDs due to their integrated design, which generates less heat and reduces power consumption for the same brightness.